The DSC 1832 security system is designed to provide flexibility and convenience for both residential and commercial applications, offering reliable protection and advanced features. This manual serves as a comprehensive guide for installers to ensure proper setup and configuration of the system, covering key aspects of installation, programming, and maintenance. Understanding the system’s capabilities and requirements is essential for a successful installation.

System Overview

The DSC PowerSeries PC1616/PC1832/PC1864 is a flexible and convenient security system designed for residential and commercial use, offering advanced features and expandable components for tailored protection. It provides a robust foundation for intrusion detection, access control, and seamless integration with additional devices, ensuring comprehensive security solutions.

2.1. Key Features of the DSC 1832 System

The DSC 1832 system offers a wide range of features tailored for both residential and commercial security needs. It supports up to 32 zones, providing extensive coverage for various sensors and detectors, and allows for multiple partitions, enabling customizable security configurations for different areas or users. Additionally, the system supports advanced communication options, including cellular and internet connectivity, ensuring reliable monitoring and remote access. Its modular design allows for seamless integration with a variety of components, such as keypads, wireless devices, and video analytics, making it highly adaptable to specific security requirements. These features ensure a robust and scalable security solution.

2.2. Compatible Components and Accessories

The DSC 1832 system is compatible with a wide range of components and accessories, enhancing its functionality and adaptability. Key compatible devices include the PC1555MX keypad, offering a touchscreen interface for intuitive control, and wireless receivers like the WS4913 and RF5132-433, enabling wireless sensor integration. Additionally, the system supports environmental sensors for smoke, carbon monoxide, and water detection, ensuring comprehensive protection. It also integrates seamlessly with video analytics devices and cameras, allowing for advanced monitoring capabilities. Furthermore, the DSC 1832 supports multiple communication modules, such as cellular and IP connectivity options, ensuring reliable system monitoring and remote access. These components enhance the system’s versatility and performance.

2.3. System Compatibility with Other Devices

The DSC 1832 system is designed to integrate seamlessly with various third-party devices, enhancing its functionality and versatility. It supports compatibility with video analytics equipment, enabling advanced object detection and monitoring capabilities. Additionally, the system is compatible with home automation systems, allowing users to control lighting, thermostats, and other smart devices through a unified interface. It also works with cellular and IP communication modules, ensuring reliable remote monitoring and system control. Furthermore, the DSC 1832 is compatible with a range of environmental sensors, including smoke, carbon monoxide, and water detectors, providing comprehensive protection for any setting. This compatibility ensures a robust and integrated security solution.

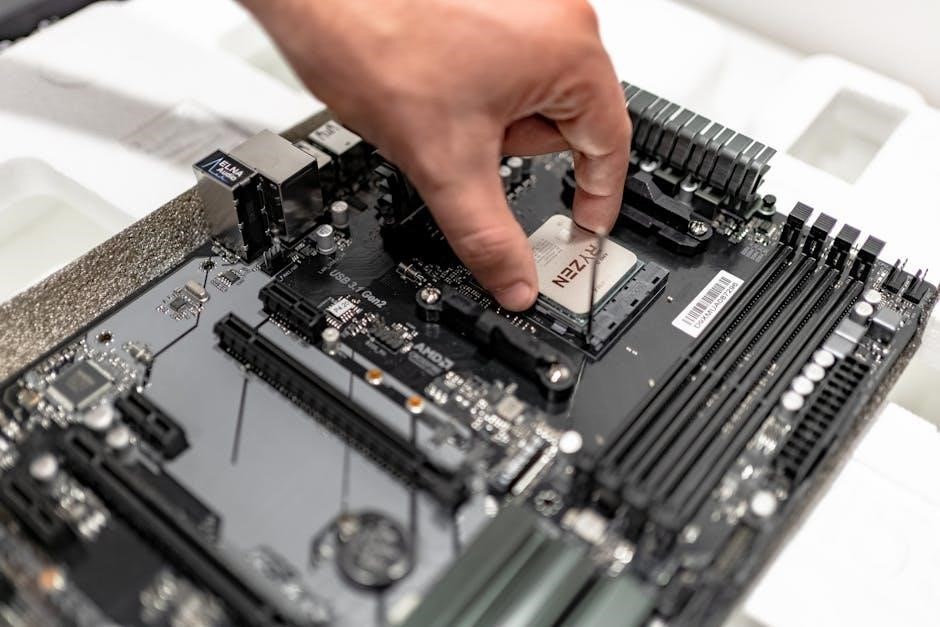

Installation Steps

Installing the DSC 1832 system requires careful planning and adherence to safety guidelines. Start with mounting the control panel, followed by wiring sensors and keypads. Ensure all connections are secure and follow the manufacturer’s recommendations for power supply and grounding. After completing the physical setup, proceed with initial power-up and system initialization to verify functionality. Always refer to the installation manual for specific instructions and safety precautions to avoid system malfunctions or damage. Proper installation ensures optimal performance and reliability of the security system;

3.1. Pre-Installation Checklist

Before installing the DSC 1832 system, ensure all components and tools are ready. Verify compatibility of sensors, keypads, and accessories with the control panel. Check local regulations and ensure the system meets all legal requirements. Confirm power supply specifications and proper grounding methods to avoid electrical issues. Review the installation manual thoroughly and plan the layout of zones and wiring. Ensure all necessary tools, such as screwdrivers and wire strippers, are available. Verify the system’s firmware is up-to-date and compatible with your setup. Plan for proper mounting locations for the control panel and keypads. Ensure all users are aware of the exit delay times and system operation basics. Follow the manufacturer’s guidelines strictly to ensure a smooth installation process.

3.2. Wiring and Connectivity Guidelines

Proper wiring is critical for the DSC 1832 system’s reliability. Ensure all connections are secure and follow the manufacturer’s wiring diagrams. Use the correct wire gauge for power and data lines to prevent signal degradation. Ground the system properly to avoid electrical interference and ensure safe operation. Connect sensors and keypads according to the zone configuration, verifying polarity to prevent damage. Use twisted pairs for zone wiring to minimize interference from other devices. Label all wires clearly for future maintenance. Double-check all connections before powering up the system to ensure functionality and safety. Refer to the installation manual for specific wiring requirements and guidelines. Adhere to local electrical codes and standards during the wiring process.

3.3. Mounting the Control Panel

Mounting the DSC 1832 control panel requires careful planning to ensure optimal functionality and accessibility. Choose a location that is secure, tamper-proof, and easily accessible for users. Ideally, the control panel should be installed near the main entry point of the premises. Ensure the panel is mounted at a comfortable height to allow easy operation. Use the provided screws and wall anchors to secure the panel firmly to the wall, preventing any movement or vibration. Avoid exposing the panel to direct sunlight or moisture to maintain reliability. If installing in a commercial setting, consider mounting it near a power source to simplify wiring. Double-check the alignment and ensure the surface is level before finalizing the installation. Proper mounting ensures the system operates efficiently and remains user-friendly. Refer to the installation manual for specific mounting hardware requirements.

3.4. Initial Power-Up and System Initialization

Upon initial power-up, the DSC 1832 control panel will automatically perform a self-test to ensure all components are functioning correctly. Connect the power supply and wait for the system to boot up. The keypad will display the system status and any detected issues. Enter the default installer code (e.g., 5555) to access the system initialization menu. Follow the on-screen prompts to configure basic settings, such as time, date, and zone definitions. Ensure all sensors and zones are properly initialized and free of faults. If any errors are detected, address them before proceeding. Refer to the manual for detailed initialization steps and troubleshooting.

Programming the System

This chapter guides you through configuring the DSC 1832 system, including programming zones, sensors, keypad settings, and user codes. Follow the manual for precise configuration steps.

4.1. Programming Zones and Sensors

Programming zones and sensors is a critical step in setting up your DSC 1832 system. Each zone corresponds to a specific sensor or group of sensors. To begin, access the system’s programming mode by entering your installer code. Navigate to the zone programming section and assign each zone a unique identifier. Define the zone type, such as “Entry/Exit” or “Perimeter,” based on the sensor’s location and function. Ensure all sensors are properly enrolled and configured to communicate with the control panel. Test each zone to confirm it triggers the appropriate response. This ensures reliable system performance and accurate alarm notifications. Refer to the manual for detailed steps and options.

4.2. Configuring Keypad Settings

Configuring keypad settings ensures smooth operation and customization of your DSC 1832 system. Key functions include arming, disarming, and triggering alarms or specific responses. To customize keypad settings, access the programming mode using the installer code. Navigate to the keypad configuration section to adjust features like keypad brightness, volume, and entry/exit delay times. Additionally, you can enable or disable keypad tones and backlighting for convenience. Save your configurations to ensure the settings are applied system-wide. Properly configured keypad settings enhance user experience and system functionality. Always test keypad responsiveness after making changes to confirm everything works as intended.

Setting up user codes and access levels on the DSC 1832 system ensures secure and personalized access control. Start by creating unique 4-6 digit user codes for each authorized individual. Assign specific access levels to determine user permissions, such as full access, arm/disarm capabilities, or limited functionality. Access levels can be customized to restrict or grant access to certain zones or features. Use the installer code to enter programming mode and navigate to the user code section. Once configured, test each user code to ensure proper functionality and access according to assigned levels. Proper setup of user codes and access levels enhances system security and user convenience. Always maintain a record of user codes for future reference. Changing the installer code on the DSC 1832 system is crucial for maintaining security and customization. Enter the current installer code (default is 5555) to access the programming menu. Navigate to the section for installer code modification and input the new code. Ensure the new code is unique and secure to prevent unauthorized access. Confirm the change by following the system prompts. Test the new code immediately to verify functionality. Document the updated installer code for future reference and ensure it is stored securely. Changing the installer code is a critical step in system setup and should only be performed by authorized personnel. Troubleshooting the DSC 1832 system involves identifying and resolving common issues like error codes, wiring problems, or sensor malfunctions. Always refer to the error code list in the manual to diagnose problems accurately. Understanding the root cause ensures efficient resolution and system reliability. Common installation errors include incorrect wiring connections, improper sensor alignment, and insufficient power supply. Programming issues may arise from misconfigured zones, incorrect keypad settings, or invalid user codes. Ensuring all connections are secure and following the manual’s wiring diagram is crucial. Additionally, verifying zone configurations and user codes during programming helps prevent operational issues. Always refer to the error codes and troubleshooting section for guidance. Proper installation and programming practices are essential to ensure system reliability and performance. The DSC 1832 system generates specific error codes and alarms to indicate issues. Codes like “Low Battery” or “Zone Fault” help identify problems quickly. Understanding these codes is crucial for effective troubleshooting. Refer to the manual for a detailed list of error codes and their meanings. Alarms may sound due to system triggers or communication failures. Addressing these issues promptly ensures system reliability. Always test the system after resolving errors to confirm proper functionality. Regular maintenance and checking error logs can help prevent recurring issues. Familiarizing yourself with error codes and alarms is key to maintaining a secure and operational system. Regular system inspections and updates are crucial for optimal performance. Ensure all components are functioning correctly and update firmware periodically. Refer to the manual for detailed procedures. Routine maintenance is essential to ensure the DSC 1832 system operates efficiently. Regularly inspect all sensors, detectors, and wiring for damage or obstructions. Verify that all wireless devices have adequate battery life and replace batteries as needed. Check the control panel for dust or physical damage and clean it periodically. Test the system’s functionality by triggering sensors and verifying alarm responses. Ensure all connections are secure and free from corrosion. Review system logs to identify recurring issues or patterns. Perform these checks every 3-6 months to maintain reliability and ensure continuous protection. Always refer to the manual for specific procedures. Regularly updating the firmware and software of the DSC 1832 system is crucial for optimal performance and security. Download the latest firmware version from the official DSC website or through authorized distributors. Before updating, ensure the system is powered up and all components are connected. Transfer the firmware file to the control panel using a compatible interface or USB device. Follow the on-screen instructions to initiate the update process. Do not interrupt the system during the update, as this may cause irreversible damage. After completion, perform a system reset to apply the changes. Always verify the update was successful by checking the system logs. Contact DSC support if issues arise during the process. The DSC 1832 system offers a robust and flexible security solution, designed to meet the needs of various applications. By following the guidelines outlined in this manual, installers can ensure proper installation, configuration, and maintenance. Regular updates and routine checks are essential to maintain system performance and security. Users are encouraged to familiarize themselves with the system’s features and operation to maximize its benefits. For further assistance, consult the official DSC resources or contact certified support professionals. Properly installed and maintained, the DSC 1832 system provides reliable protection and peace of mind for years to come.4.3. Setting Up User Codes and Access Levels

4.4. Changing the Installer Code

Troubleshooting Common Issues

5.1. Common Installation and Programming Errors

5.2. Understanding Error Codes and Alarms

Maintenance and Updates

6.1. Routine Maintenance Checks

6.2. Updating Firmware and Software