A manual transmission torque converter is a component designed to enhance the connection between the engine and transmission in manual vehicles‚ optimizing power delivery and efficiency.

1.1 What is a Manual Transmission Torque Converter?

A manual transmission torque converter is a hybrid component that combines the efficiency of a manual gearbox with the smooth power delivery of a torque converter‚ allowing drivers to maintain control while enhancing low-speed maneuverability and reducing clutch wear. It integrates seamlessly with manual shifting mechanisms to optimize performance and driver experience.

1.2 Historical Background and Evolution

The concept of a manual transmission torque converter originated from advancements in automatic transmissions‚ where torque converters were first used to smooth power delivery. Over time‚ engineers adapted this technology for manual systems‚ blending the efficiency of manual gearboxes with the smooth operation of torque converters to enhance performance and driver experience.

Components of a Manual Transmission Torque Converter

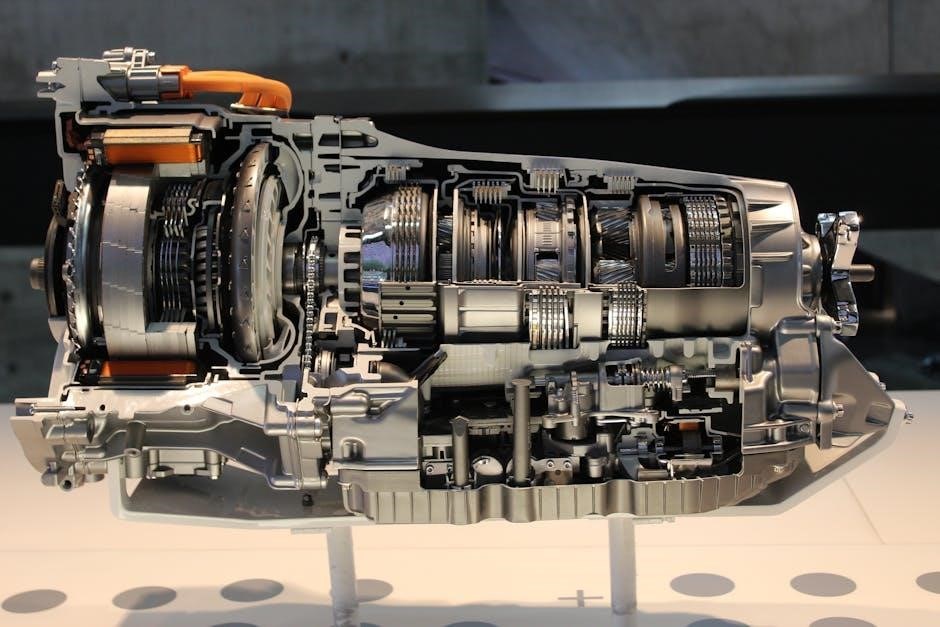

A manual transmission torque converter system includes a torque converter‚ clutch assembly‚ gear system‚ and electronic controls‚ working together to optimize power transfer and manual shifting efficiency.

2.1 Torque Converter Basics

A torque converter is a fluid-filled coupling device that connects and disconnects the engine from the transmission‚ enabling smooth power transfer and torque multiplication. It consists of a pump impeller‚ turbine‚ and stator‚ working together to manage fluid flow and optimize engine performance during acceleration and deceleration phases.

2.2 Manual Transmission Components

A manual transmission includes a clutch assembly‚ gear system‚ input/output shafts‚ and synchronizers. These components work together to provide driver control over gear shifts‚ enabling precise power transfer from the engine to the wheels. The clutch engages/disengages the engine from the transmission‚ while gears and shafts facilitate speed and torque adjustments.

2.3 Integration of Torque Converter in Manual Transmission

Integrating a torque converter into a manual transmission involves replacing the traditional clutch with a converter that smooths power delivery. This setup combines the efficiency of manual shifting with the seamless torque multiplication of an automatic‚ offering enhanced control and performance during acceleration and gear changes.

Working Principle of a Manual Transmission Torque Converter

The torque converter transfers engine power to the transmission‚ minimizing speed loss during gear shifts. It optimizes torque delivery‚ enabling smooth acceleration and maintaining driver control over manual gears.

3.1 How Torque Converter Operates in Manual Transmission

The torque converter in a manual transmission operates by optimizing torque delivery during gear shifts. It minimizes power loss and ensures smooth acceleration‚ allowing the engine to maintain connection with the transmission without relying on the clutch for partial engagement‚ thus enhancing overall driving efficiency and control.

3.2 Role of Clutch and Gear System

The clutch and gear system in a manual transmission enable precise driver control over torque and speed. The clutch disconnects the engine during gear shifts‚ while the gear system provides mechanical advantage‚ allowing drivers to optimize acceleration and performance‚ essential for manual operation.

3.3 Interaction Between Torque Converter and Manual Gears

The torque converter in a manual transmission interacts with gears by smoothing power delivery during low-speed operations. It minimizes clutch and gear wear while maintaining driver control‚ providing a seamless connection between the engine and transmission‚ even in manual shifting scenarios.

Benefits of Using a Manual Transmission Torque Converter

Enhances fuel efficiency‚ improves performance with smoother power delivery‚ offers better control‚ simplifies driving in traffic‚ and reduces wear on clutch and gears‚ lowering maintenance costs.

4.1 Improved Fuel Efficiency

A manual transmission torque converter optimizes engine power delivery‚ reducing unnecessary fuel consumption. By minimizing energy loss during gear shifts‚ it enhances overall efficiency‚ especially in city driving‚ where frequent acceleration and deceleration occur. This results in better mileage compared to traditional manual transmissions without a torque converter.

4.2 Enhanced Performance and Control

The torque converter in a manual transmission improves acceleration and responsiveness by smoothing power delivery during gear shifts. Drivers experience more precise control‚ especially in high-performance scenarios‚ allowing for quicker and more seamless transitions between gears without sacrificing the manual driving experience.

4.3 Simplified Driving Experience

The torque converter reduces the need for constant clutch engagement‚ making manual driving less strenuous in traffic. It offers smoother starts and reduces the learning curve for new drivers‚ blending the ease of automatics with the control of manuals for a more relaxed yet engaging driving experience.

4.4 Cost-Effectiveness

A manual transmission torque converter enhances fuel efficiency and reduces mechanical stress‚ lowering overall operating costs. By optimizing gear shifts‚ it minimizes wear on components‚ reducing repair and replacement expenses‚ making it a cost-effective solution for drivers seeking improved performance without heightened maintenance burdens.

Challenges and Limitations

Implementing a manual transmission torque converter poses technical challenges‚ requires driver adaptation‚ and involves complex maintenance‚ making it less accessible for inexperienced users and resource-intensive to sustain.

5.1 Technical Difficulties in Implementation

Integrating a torque converter into a manual transmission requires precise synchronization of components‚ complex mechanical adjustments‚ and overcoming issues like mechanical stress during gear shifts‚ ensuring proper engagement without slippage‚ and adapting to driver-controlled shifting dynamics.

5.2 Driver Adaptation and Learning Curve

Drivers transitioning to a manual transmission torque converter face challenges in mastering the unique feel of the system‚ requiring precise coordination between clutch operation and gear shifts to avoid jerky acceleration and ensure smooth power delivery.

5.3 Maintenance and Repair Complexity

Maintenance and repair of manual transmission torque converters involve specialized tools and expertise‚ with intricate components requiring precise adjustments. Regular inspections and timely replacements of worn parts are crucial to prevent costly failures and ensure optimal performance.

Applications of Manual Transmission Torque Converter

Manual transmission torque converters are ideal for high-performance vehicles‚ hybrid and electric cars‚ and racing applications‚ offering precise control and efficient power transmission in diverse driving scenarios.

6.1 High-Performance Vehicles

In high-performance vehicles‚ manual transmission torque converters optimize engine power delivery‚ enabling rapid acceleration and precise control. They minimize torque loss‚ making them ideal for racing and sport cars that demand instant responsiveness and maximum efficiency during high-speed operations.

6.2 Hybrid and Electric Vehicles

Manual transmission torque converters are increasingly integrated into hybrid and electric vehicles to enhance energy efficiency and smooth power transitions. They optimize torque delivery between combustion engines and electric motors‚ improving overall performance and reducing energy consumption in eco-friendly automotive solutions.

6.3 Racing and Specialty Cars

Manual transmission torque converters are widely used in racing and specialty cars to enhance performance and control. They provide precise torque management‚ enabling faster acceleration and better responsiveness‚ making them ideal for high-performance applications where driver control and optimized power delivery are critical.

Installation and Modification

Installing a manual transmission torque converter requires mechanical expertise and specialized tools. Proper alignment and calibration are crucial for optimal performance. This modification can significantly enhance vehicle responsiveness and driver control‚ but demands precise technical knowledge to execute effectively.

7.1 Step-by-Step Installation Guide

Begin by disconnecting the battery and draining transmission fluid. Remove the transmission pan and locate the torque converter bolts. Loosen these bolts gradually while maintaining engine crankshaft stability. Carefully pull the converter straight out‚ ensuring no damage to the transmission housing. Replace the old converter with the new one‚ aligning the splines precisely. Tighten the bolts in a star pattern to avoid warping the converter housing. Reinstall the transmission pan and refill with the recommended fluid. Finally‚ reconnect the battery and test the system for leaks or unusual noises. Proper installation ensures smooth operation and prevents costly repairs. Always refer to the manufacturer’s instructions for specific torque specifications and safety precautions. If unsure‚ consult a professional mechanic to guarantee accuracy and safety. This process requires patience and attention to detail to avoid any complications. Following these steps meticulously will ensure a successful installation and optimal performance of the manual transmission torque converter. Regular maintenance and inspections are recommended to uphold the system’s integrity and functionality over time.

7.2 Common Modifications for Enhanced Performance

- Upgrade the clutch pack for improved grip and durability.

- Enhance the one-way clutch system for smoother engagement.

- Install a high-performance torque converter with optimized stall speeds.

- Add a brake system behind the converter for better control during gear changes.

- Refine the transmission housing for increased strength and stability;

Maintenance and Repair

Regular inspection of the clutch and torque converter is essential to ensure smooth operation. Addressing worn-out components early prevents major damage. Common repairs include replacing clutch packs and ensuring proper lubrication for optimal performance and reliability.

8.1 Regular Inspection and Servicing

Regular inspection ensures optimal performance by identifying wear on components like the clutch and gears; Check for fluid leaks and ensure proper lubrication. Servicing every 30‚000 to 60‚000 miles helps maintain smooth operation and prevents premature wear‚ ensuring the torque converter functions efficiently and reliably over time‚ avoiding costly repairs.

8.2 Troubleshooting Common Issues

Common issues include slippage‚ hesitation‚ or unusual noises. Check for worn clutch packs or low fluid levels. If gears grind‚ alignment or synchro wear may be the cause. Addressing these issues promptly prevents further damage and ensures smooth operation of the manual transmission torque converter system.

8.3 Replacement of Worn-Out Components

Replacing worn-out components in a manual transmission torque converter involves inspecting and identifying faulty parts such as clutch packs‚ bearings‚ or seals. These parts should be disassembled‚ replaced with genuine components‚ and reassembled with proper alignment. Regular maintenance and timely replacements ensure optimal performance and longevity of the system.

Future Trends and Developments

Future trends include integrating manual transmission torque converters with autonomous systems‚ advancing materials for higher efficiency‚ and exploring hybrid solutions to optimize performance and fuel efficiency.

9.1 Advancements in Torque Converter Technology

Advancements in torque converter technology focus on improving efficiency‚ reducing weight‚ and enhancing compatibility with modern drivetrains. Innovations like lock-up torque converters and adaptive systems optimize performance. Research into lightweight materials and smarter clutch systems aims to maximize fuel efficiency while maintaining responsiveness in manual transmissions.

9.2 Integration with Autonomous Driving Systems

Integrating manual transmission torque converters with autonomous driving systems presents unique challenges. The torque converter must seamlessly interact with autonomous controls to ensure smooth‚ precise gear shifts and power delivery. Advanced sensors and algorithms are being developed to synchronize the torque converter’s operation with autonomous driving functions‚ enhancing overall vehicle responsiveness and efficiency. This integration aims to maintain the performance benefits of manual transmissions while adapting to the demands of autonomous systems‚ though it remains a complex and evolving area of research and development.

9.3 Potential Alternatives to Torque Converters

Alternatives to torque converters in manual transmissions include dual-clutch transmissions (DCTs) and continuously variable transmissions (CVTs). DCTs use dual clutches for faster shifts‚ while CVTs offer infinite gear ratios for smoother acceleration. Both technologies aim to improve efficiency and performance‚ potentially replacing traditional torque converters in future manual transmission systems.

Frequently Asked Questions

Common questions about manual transmission torque converters include comparisons to automatics‚ installation feasibility‚ and maintenance costs‚ providing clarity for drivers seeking optimal performance and efficiency.

10.1 Is a Manual Transmission Torque Converter Better Than Automatic?

A manual transmission torque converter can offer better fuel efficiency and driver control compared to automatics‚ but it depends on driving habits and vehicle type. Automatics provide convenience‚ while manuals suit performance-oriented drivers. The choice hinges on balancing efficiency‚ control‚ and ease of use based on individual preferences and needs.

10.2 Can I Install a Torque Converter in My Existing Manual Transmission?

Installing a torque converter in a manual transmission is unconventional‚ as manuals typically use a clutch. While technically possible with modifications‚ it may not provide significant benefits and could complicate the system. Consult a professional to assess feasibility and avoid potential mechanical conflicts.

10.3 What Are the Maintenance Costs Compared to Traditional Manual Transmissions?

Maintenance costs for a manual transmission with a torque converter may be slightly higher due to the added complexity. Regular fluid checks and potential wear on the converter itself can increase expenses compared to a traditional manual setup‚ which is generally simpler and cheaper to maintain.

The manual transmission torque converter offers a unique blend of efficiency and performance‚ providing drivers with enhanced control while maintaining the benefits of modern transmission technology.

11.1 Summary of Key Points

The manual transmission torque converter combines the efficiency of manual transmissions with enhanced power delivery‚ offering improved fuel economy‚ smoother operation‚ and better driver control. It integrates seamlessly with manual gears‚ providing a hybrid solution that bridges traditional manual and automatic transmission benefits. Ideal for high-performance vehicles‚ it represents a modern evolution in transmission technology.

11.2 Final Thoughts on Manual Transmission Torque Converter

The manual transmission torque converter offers a unique blend of driver control and automated efficiency‚ making it ideal for high-performance and racing applications. Its ability to optimize power delivery without sacrificing the manual driving experience positions it as a promising advancement in transmission technology‚ catering to enthusiasts and specialized vehicles.

References and Further Reading

- Manufacturer guides for manual transmissions and torque converters.

- Academic papers on transmission technology advancements.

- Online forums discussing manual transmission torque converter applications.

- Technical documentation for installation and maintenance.

12.1 Recommended Resources for Deep Dive

For an in-depth understanding‚ explore manufacturer guides‚ academic papers‚ and technical documentation. Online forums like EricTheCarGuy and transmission repair manuals offer practical insights. Additionally‚ technical service bulletins and specialized automotive websites provide detailed information on manual transmission torque converter systems and their applications.

- Technical service bulletins for specific vehicle models.

- Automotive engineering journals and research studies.

- Specialized forums and communities like EricTheCarGuy.

- Detailed repair manuals for manual transmissions.

12.2 Academic Papers and Research Studies

Academic papers and research studies on manual transmission torque converters are available in engineering journals and databases like IEEE Xplore‚ SAE International‚ and Google Scholar. These studies explore design innovations‚ efficiency improvements‚ and optimal integration with manual transmissions‚ offering insights into enhancing performance and reducing power loss.

- IEEE Xplore for cutting-edge research.

- SAE International for automotive engineering studies.

- Google Scholar for comprehensive analyses.

12.3 Manufacturer Guides and Technical Documentation

Manufacturer guides and technical documentation provide detailed specifications‚ installation procedures‚ and troubleshooting tips for manual transmission torque converters. Companies like GM‚ Ford‚ and BorgWarner offer comprehensive manuals‚ ensuring compatibility and optimal performance. These resources are essential for engineers‚ technicians‚ and enthusiasts to understand and work with torque converter systems effectively.

- Consult official manufacturer websites for specific models.

- Refer to service bulletins for updates and modifications.

- Use technical diagrams for accurate installations and repairs.