The Cessna 182Q parts manual is an essential resource for maintaining, repairing, and upgrading your aircraft. It provides detailed diagrams, part numbers, and maintenance procedures, ensuring compliance with safety standards and optimal performance. This comprehensive guide is indispensable for owners, mechanics, and enthusiasts, covering everything from routine inspections to complex repairs. Use it to identify components, troubleshoot issues, and perform upgrades efficiently.

Overview of the Cessna 182Q Aircraft

The Cessna 182Q Skylane is a four-seat, single-engine piston aircraft renowned for its reliability and performance. Introduced in 1976, the 182Q features a 230-horsepower Continental O-470 engine, offering excellent cruising speeds and range. Its durable design, tricycle landing gear, and spacious cabin make it a popular choice for both personal and training use. The aircraft’s versatility, combined with its proven track record, has solidified its place in aviation history and general aviation fleets worldwide.

Importance of the Parts Manual for Maintenance and Repair

The Cessna 182Q parts manual is a critical resource for ensuring safe and effective aircraft maintenance. It provides detailed diagrams, part specifications, and repair procedures, enabling mechanics and owners to identify and address issues accurately. By following the manual, users can troubleshoot problems, order correct replacements, and perform routine maintenance efficiently. This ensures compliance with safety standards, prevents costly errors, and maintains the aircraft’s airworthiness and performance. It is indispensable for anyone involved in the upkeep of the Cessna 182Q.

Aircraft History and Development

The Cessna 182Q Skylane, introduced in 1978, is a proven aircraft known for its reliability and performance. Its design emphasizes durability and versatility, making it a popular choice for both private and commercial aviation.

Brief History of the Cessna 182Q Model

The Cessna 182Q Skylane was introduced in 1978 as part of the 182 series, known for its durability and versatility. It featured a robust airframe and reliable Lycoming engine, making it a favorite among pilots. Over the years, the model underwent minor design improvements while retaining its core strengths.

Produced until 1985, the 182Q remains popular for its performance and ease of maintenance. Its reputation as a reliable workhorse has enduring appeal, supported by comprehensive parts manuals that ensure longevity and airworthiness;

Design Evolution and Key Features

The Cessna 182Q Skylane features a robust all-metal airframe and fixed tricycle landing gear, designed for durability and stability. Its Lycoming O-470 engine delivers reliable power, while the manual’s detailed specifications ensure proper maintenance. The design emphasizes ease of operation and versatility, making it suitable for both personal and professional use. The parts manual plays a crucial role in maintaining these systems, ensuring optimal performance and longevity.

Understanding the Parts Manual

The Cessna 182Q parts manual is a user-friendly guide providing detailed diagrams, part numbers, and maintenance procedures. It helps mechanics and owners identify components and troubleshoot issues effectively, ensuring safety and optimal performance. The manual’s clarity and comprehensive part listings make it an indispensable tool for repairs and upgrades, keeping your aircraft airworthy and reliable.

Structure and Organization of the Manual

The Cessna 182Q parts manual is structured logically for easy navigation; It begins with an index, followed by detailed sections covering airframe, engine, and avionics. Each component is listed with part numbers, descriptions, and diagrams. The manual includes numbered listings for quick reference and cross-referenced pages for related parts. Appendices provide technical specifications and compliance standards. This clear organization ensures users can efficiently locate and identify parts, facilitating accurate maintenance and repairs.

Key Components and Systems Covered

The Cessna 182Q parts manual covers essential systems like airframe, engine, avionics, electrical, hydraulic, and landing gear. It details components such as fuel injection, ignition, navigation, and landing gear mechanisms. The manual specifies part numbers, torque values, and inspection intervals, aiding in precise maintenance. It ensures compliance with safety standards, making it vital for effective aircraft upkeep.

Maintenance Requirements and Procedures

Routine inspections and scheduled maintenance are the foundation of aircraft upkeep. Adhering to manufacturer guidelines ensures safety, performance, and longevity of the Cessna 182Q.

Routine Maintenance Tasks and Schedules

Maintaining the Cessna 182Q involves regular tasks like oil changes, tire pressure checks, and avionics system inspections. Adhering to the manual’s schedule ensures optimal performance and safety. Each task is detailed with specific intervals, such as every 50 hours for certain inspections. Following these guidelines helps prevent issues and extends the aircraft’s lifespan. Compliance with these schedules is crucial for safe operation and regulatory adherence.

Inspection Procedures and Compliance Standards

Regular inspections are critical for ensuring the Cessna 182Q’s airworthiness. The parts manual outlines detailed procedures for pre-flight, 50-hour, and annual inspections. These include checking flight control surfaces, landing gear, and engine components for wear or damage. Compliance with FAA standards is mandatory, and all findings must be documented. Proper inspection practices help maintain safety, prevent mechanical failures, and ensure regulatory adherence, making them a cornerstone of responsible aircraft ownership and operation.

Troubleshooting Common Issues

Troubleshooting involves identifying and diagnosing problems using the parts manual. Common issues include oil filter mismatches and electrical system malfunctions. Expert Q&A sessions provide solutions.

Identifying and Diagnosing Common Problems

The Cessna 182Q parts manual aids in identifying issues like oil filter mismatches and electrical malfunctions. Detailed diagrams and part listings help diagnose problems accurately. Experts from AOPA provide additional insights, ensuring owners and mechanics can resolve issues effectively; Troubleshooting techniques, such as checking application charts for correct filters, are emphasized. This section ensures that common problems are addressed systematically, promoting safety and efficiency in aircraft maintenance.

Repair Techniques and Solutions

The Cessna 182Q parts manual offers step-by-step repair techniques for common issues, such as oil filter replacements and electrical system fixes. Experts like Mike Busch and Colleen Sterling provide guidance on effective solutions. Proper tools and adherence to manual instructions ensure repairs are done safely and efficiently. Using the correct parts, like the specified 48103 filter, is crucial for maintaining performance and safety. Regular documentation of repairs aids in future maintenance planning.

Upgrades and Modifications

The Cessna 182Q parts manual details performance enhancements, such as engine upgrades and avionics improvements, to optimize aircraft capabilities. Explore modifications to enhance safety and efficiency.

Performance Enhancements and Upgrades

Upgrading the Cessna 182Q can significantly improve its performance. Engine modifications, such as installing a more powerful propeller or a turbocharger, can enhance climb rates and cruising speeds. Additionally, aerodynamic tweaks like wingtip extensions can reduce drag and boost fuel efficiency. Avionics upgrades, such as advanced GPS systems, also contribute to safer and more efficient flights. These upgrades ensure the aircraft remains modern and high-performing.

Avionics and Instrument Upgrades

Upgrading the avionics and instruments in your Cessna 182Q enhances safety, efficiency, and navigation capabilities. Modern systems like the Garmin G1000 offer advanced features such as touchscreen controls, synthetic vision, and real-time weather updates. The parts manual provides detailed guidance for installing these upgrades, ensuring compatibility and compliance with aviation standards. Regular updates to avionics also improve reliability and reduce pilot workload, making flying safer and more enjoyable.

Sourcing Parts and Suppliers

Sourcing parts for the Cessna 182Q involves contacting authorized dealers for genuine components. Aftermarket options offer cost savings but require careful verification of quality and compliance.

Authorized Dealers and Suppliers

Authorized dealers provide genuine Cessna parts, ensuring quality and compliance with factory standards. They maintain extensive inventories and offer expert support, making them the most reliable source for components. These suppliers are certified by Cessna, guaranteeing authenticity and performance. Using authorized dealers minimizes risks and ensures warranty compliance, making them the top choice for aircraft maintenance and upgrades. Their expertise and reliability are unmatched in the industry.

Aftermarket Parts and Cost Considerations

Aftermarket parts offer cost-effective alternatives to OEM components, often with comparable quality. They can significantly reduce maintenance expenses while meeting performance standards. However, selecting trusted manufacturers is crucial to ensure reliability and safety. Warranty coverage and compatibility should be verified before purchase. Balancing cost and quality is essential for budget-conscious owners, but never compromise on critical safety components. Always consult the parts manual for compatibility and compliance with aviation regulations.

Safety Considerations and Precautions

Adhering to safety protocols is crucial when handling aircraft parts. Always wear protective gear and ensure proper tool usage to prevent injuries and damage. Follow established guidelines and manufacturer recommendations to maintain aircraft airworthiness and ensure safe flight operations. Regular inspections and compliance with safety standards are vital to uphold the integrity of the aircraft and protect its occupants. Safety should never be compromised during maintenance tasks.

Safe Handling of Aircraft Parts

Proper handling of Cessna 182Q parts is critical to ensure safety and prevent damage. Always use appropriate tools and protective gear, such as gloves and safety glasses, when handling components. Store parts in a clean, dry environment away from direct sunlight to maintain their condition. Follow torque specifications and tightening sequences to avoid damage during installation. Regularly inspect parts for wear or corrosion before installation. Proper handling ensures aircraft integrity and operational safety.

Compliance with Safety Regulations

Adhering to safety regulations is paramount when working with the Cessna 182Q. All maintenance must comply with FAA guidelines and manufacturer instructions. Ensure all repairs are documented and inspected by certified professionals. Regular reporting of safety deviations and malfunctions helps identify hazards and improve practices. Compliance guarantees adherence to industry standards, ensuring the aircraft’s airworthiness and operational safety. Always reference the latest regulatory updates and manufacturer recommendations to maintain compliance and safety.

Glossary of Technical Terms

This section defines key terminology used in the Cessna 182Q parts manual. From avionics to engine components, it clarifies technical jargon, ensuring clear understanding for maintenance and repair tasks.

Definitions of Key Terminology

Landing Gear System: The assembly enabling aircraft takeoff, landing, and ground operations. Lycoming IO-540-D4A5 Engine: The powerful engine model powering the Cessna 182Q. Horizon Level: The instrument indicating aircraft attitude relative to the horizon. Primary Flight Display (PFD): A digital screen showing essential flight data. Vy (Best Rate of Climb Speed): The speed for maximum climb efficiency. VOR (VHF Omnidirectional Range): A navigation aid providing directional guidance. These terms are crucial for understanding and maintaining the aircraft.

Abbreviations and Acronyms Used

Common abbreviations in the Cessna 182Q parts manual include ATC (Air Traffic Control), IFR (Instrument Flight Rules), and VFR (Visual Flight Rules). Acronyms like TBO (Time Between Overhaul) and EGT (Exhaust Gas Temperature) are used for engine maintenance. Avionics terms such as GPS (Global Positioning System), VOR (VHF Omnidirectional Range), and DME (Distance Measuring Equipment) are also included. These abbreviations streamline communication and documentation in the manual.

The Cessna 182Q parts manual is an invaluable resource for maintaining and upgrading your aircraft, ensuring safety and performance. It aids in making informed decisions for repairs and enhancements.

The Cessna 182Q parts manual is a comprehensive guide for aircraft maintenance, repair, and upgrades. It provides detailed diagrams, part numbers, and procedures to ensure compliance with safety standards. The manual aids in troubleshooting, repairing, and upgrading components efficiently. It is an essential resource for owners, mechanics, and enthusiasts, offering clear instructions for routine inspections and complex repairs. Regular reference to this manual ensures optimal performance, safety, and longevity of the aircraft.

Final Thoughts on Effective Use of the Parts Manual

Effective use of the Cessna 182Q parts manual requires regular reference to ensure accurate repairs and maintenance. Familiarize yourself with its structure and terminology to navigate efficiently. Stay updated with the latest revisions and adhere to manufacturer guidelines for safety and compliance. By leveraging this resource, you can extend the aircraft’s lifespan and maintain peak performance. Always consult professionals for complex tasks and utilize the manual as your primary guide for all maintenance activities.

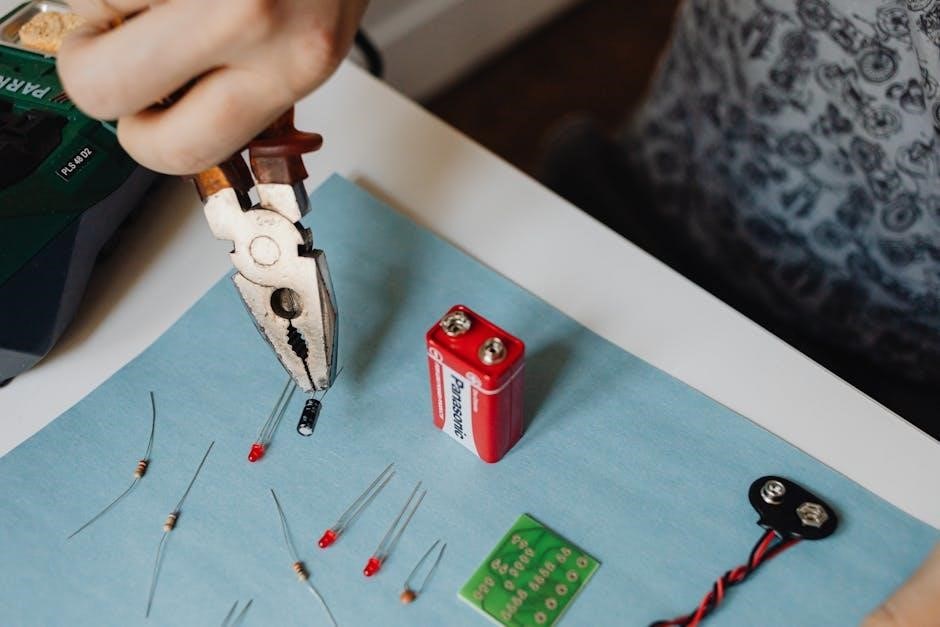

Tools and Equipment

Essential tools include wrenches, screwdrivers, pliers, and specialized gear specified in the manual. Use high-quality equipment to ensure proper maintenance and safety while working on the aircraft.

Essential Tools for Maintenance

Essential tools for maintaining the Cessna 182Q include wrenches, screwdrivers, pliers, and specialized tools like torque wrenches and rivet guns. High-quality tools ensure proper tightening and alignment. Consumables such as fasteners, sealants, and lubricants are also critical. Using the correct tools helps meet safety and regulatory standards, preventing damage and ensuring reliable operation. Always refer to the parts manual for specific requirements and recommendations to maintain compliance and efficiency during maintenance tasks.

Specialized Equipment Requirements

Maintenance of the Cessna 182Q requires specialized equipment, such as hydraulic pressure test kits, fuel system testers, and avionics diagnostic tools. A Form 5 Evaluation tool is essential for G1000 systems. Specific filter wrenches and torque wrenches are also needed for precise adjustments. Additionally, equipment like rivet guns and sheet metal tools are necessary for structural repairs. Always use OEM-approved equipment to ensure accuracy and compliance with manufacturer specifications for safe and efficient maintenance operations.